Concept

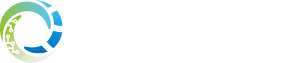

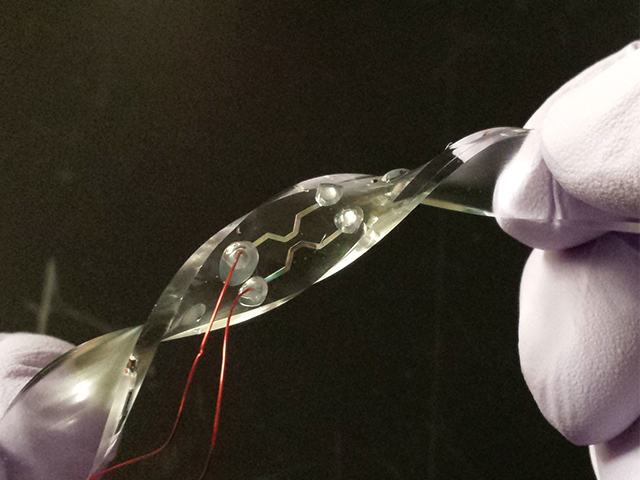

Development of stretchable sensors using liquid metals

We are developing stretchable sensors using liquid metals (e.g., eutectic gallium-indium) and micro-fabrication techniques. One of the many applications using flexible sensors is as wearable devices. The near future will see a greater demand for stretchability of wearable devices to allow deformation of the body to be followed more freely and closely and for users to feel less discomfort. We are developing stretchable sensors using liquid metals and rubber materials. We have realized liquid metal-based sensors for pressure, temperature, humidity, and gas concentration, and will expand this technology by making other types of sensors.

References

H. Ota, K. Chen et al. Nature Communication (2014) Y. Gao*, H. Ota* et al. Advanced Materials (2017) *Equal contribution

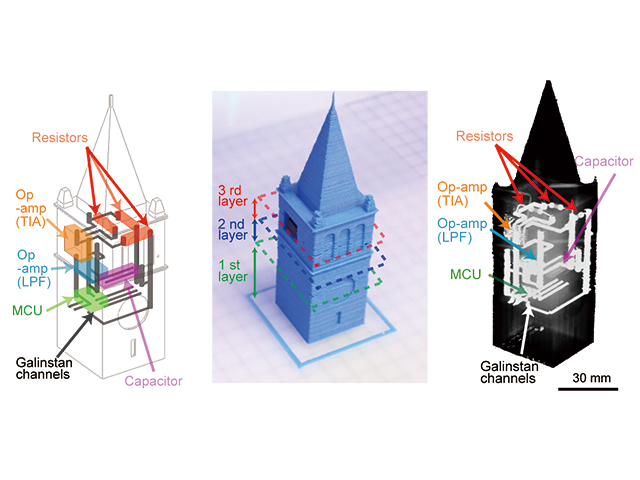

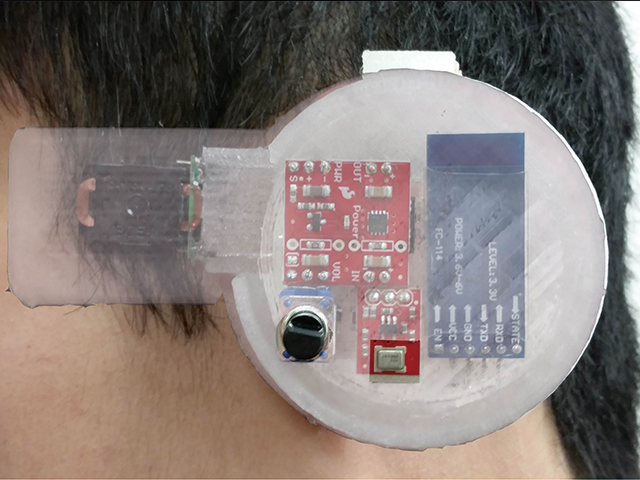

Development of healthcare and medical smart devices based on 3D printing and liquid metal sensors

We are developing next-generation smart devices for healthcare and medical applications using 3D circuits, which are fabricated by 3D printing of flexible rubber-like materials and liquid metals. These smart devices can monitor bio-markers like heartbeat, pulse, and body temperature continuously by connecting with smart phones. We have realized a smart glove with a resistive heater and a smart wearable, ear device—we call it an earable device—for real-time measurement of deep body temperatures based on this technology. We are contributing to healthier lives by developing these healthcare and medical smart devices.

References

H. Ota et al. Advanced Materials Technologies (2016) H. Ota et al. ACS Sensors (2017)

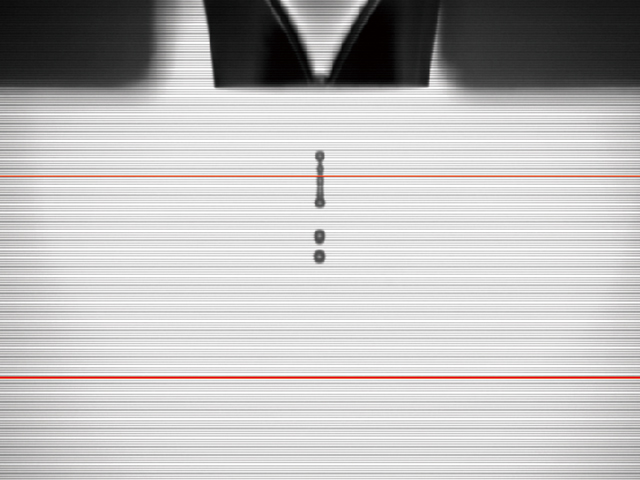

Development of new fabrication processes for smart devices based on printing

We are developing new fabrication processes for devices composed of soft materials, which are based on such printing processes as screen printing, inkjet printing, and roll-to-roll (R2R) printing. These fabrications assemble devices by patterning conductive liquid materials like liquid metals and carbon nanotubes. Our goal is development of a printing process having the capability for high resolution patterning, which is optimized by the four fundamental forces in mechanics.

Inkjet printing process for making smart devices

Inkjet printing process for making smart devicesReferences

D. Kiriya et al. Journal of the American Chemical Society (2014)